I finally had some time to get back to working on the plane. I wrapped up the plenum installation by drilling K1000-8 nutplates to the baffles and counter sinking for some countersunk washers.

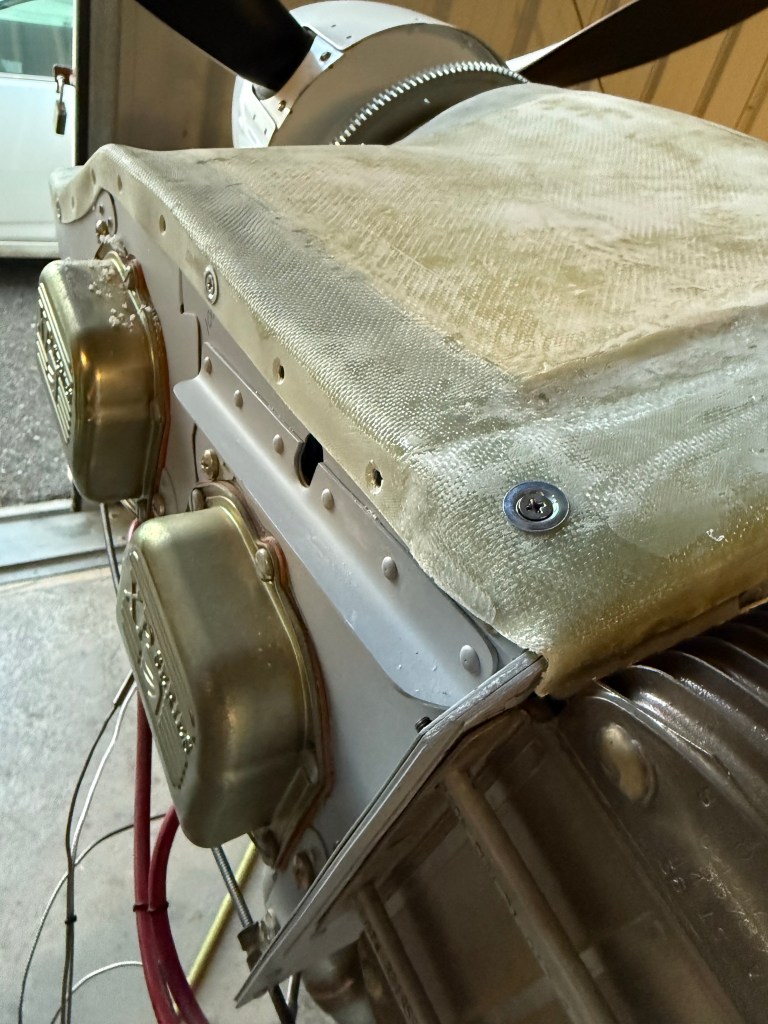

Now that the plenum is fully drilled, I can paint it and prep it for final installation. Here is the plenum with one of the screws installed.

Another angle. I decided to counter sink and use the washers to help distribute the load of the pressure within the plenum. The total force inside the plenum could be a couple hundred pounds when I am in cruise, so I wanted to ensure that the plenum is securely attached to the baffles.

Once the plenum is painted, I will put a bead of high-temp silicone caulking on the inside, where the lip of the baffles are, to create an air-tight seal when the plenum gets installed.

Leave a comment