Yesterday I hit a huge milestone. After many weeks of prep for this moment, I have officially installed my first airplane engine! It was more difficult than I thought, but everything lined up great once I figured out the technique.

First a huge thank you to my uncle for helping me out, definitely needed his strength and even one of his tools.

We began by repositioning the plane into the shade, and I propped the tail up on one of my saw horses to bring the nose down a bit.

We then hoisted the engine and rolled it to the plane.

It was a bit nerve wracking, but the hoist was pretty stable.

The alignment process was quite tricky, and getting even one of the bolts to align took some wiggling and repositioning.

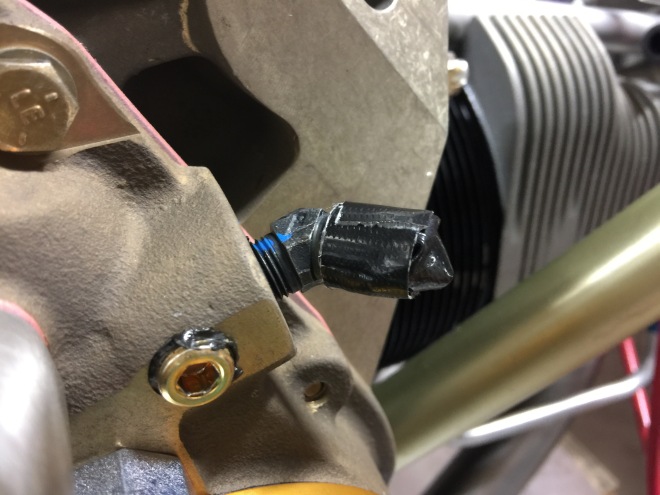

With a dynafocal type 1 Mount, the bolts converge on the CG of the engine when tightened. This made it difficult to align everything initially until we tightened everything down.

Removing the hoist and letting it hang was one of the coolest things ever!

I got everything back into the garage and will begin installing some of the engine instrumentation and continue moving forward!